The English version.

We offer modern European technology for the processing of wood and wood waste coal.

Some common characteristics of the two retort furnaces

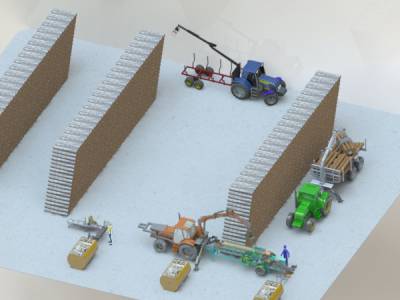

Service 1 is sufficient for the operator 4 furnaces.

Quality: coal can be made for the purposes of human consumption, catering; or industrial purposes

Energy efficiency: The charcoal furnaces operate by burning wood pyrolysis gases.

Raw materials: as a raw material and any suitable lumpy waste as croaker, truncation, ballast, big chips ...

Safety: the oven meet all the requirements and standards of occupational safety, environmental, fire and safety, etc ..

Advantages: proper organization of gas flow, heat transfer, complete and efficient combustion of the pyrolysis gases, the greatest relative yield at the lowest cost per unit of output, make the most of the furnace efficiency and environmental performance; mechanization, automation create the best working conditions in the charcoal burning; Various design solutions provide reliable, durable and safe operation of the furnace

.

For example,

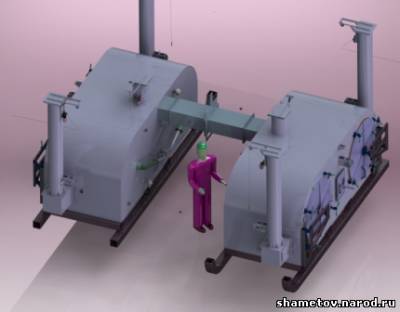

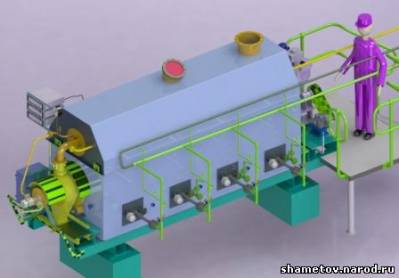

1. Front two retort charcoal kiln, such PF2RG-60. Standard.

Performance in the last month: 60 tons \ month.

Performance of birch wood: 330-450 cubic meters \ month.

Dimensions overall: 8050x2850x5350

Weight retort with raw materials up to 4 tons

Requirement: forklift, load-carrying capacity of not less than 5 tons.

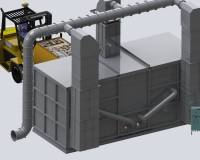

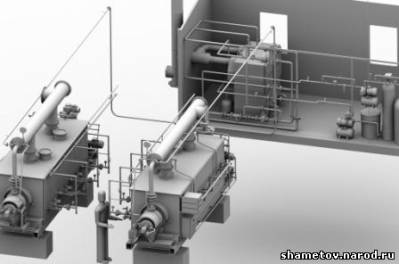

2. Furnaces for the product of charcoal, with a vertical retort

1.3. Of channel drying, cooling pad, pad loading and unloading

Features

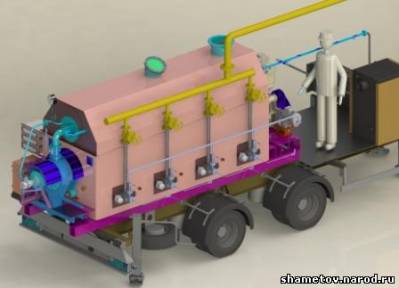

Type 1. Dvuh retort coal furnace PG2R-60 with vertical retorts and 2 PF2R retort coal furnace with horizontal retorts. . At the same size footprint, that two vertical retort retort furnace; Work on technology services and weight decreased furnace retort volume increased mobility and increased ease of maintenance.

Now you do not need cranes, hoists. Enough to have a boot loader.

1.1. PG2R furnace bowl and a vertical retort with a capacity of birch charcoal, 40 - 85 tons \ month (1000 tons \ year), depending on the size AA

1.2. PF2R furnace, horizontal arrangement and glass retort with a capacity for birch charcoal, from 50 - 135 tons \ month (1,600) tons \ year), depending on the size

Charcoal burning oven, the most cost-effective, with better working conditions in coal burning, with the highest specific output of charcoal, with a significant reduction in labor costs, with afterburning pyrolysis gases, compared with other retort furnaces.

Number of retorts = 20 (8) units. Accordingly.

Staff: one (1) person can serve four (five) of the furnace.

Quality: Coal can be made for the purposes of human consumption, catering; and industrial purposes, in accordance with the Standard, or other standards such as ISO, DIN, ANSI ...

Raw materials: 5.5-7 cubic meters per 1 ton, depending on the wood. Additional fuel costs, except for the use of pyrolysis gases is required. Raw materials are suitable as well, and any large-size waste: croaker, truncation, ballast, chips ...

Furnaces, meet the requirements of environmental protection, fire and industrial safety.

Stoves are made to order, or we can offer electronic drawings and 3D-models. Investment is needed. Possible joint ventures.

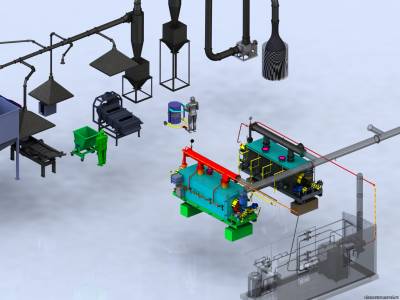

Furnaces and installations for the production of charcoal and sorbents; reactivation and regeneration active (activated) coals and sorbents.

For example,

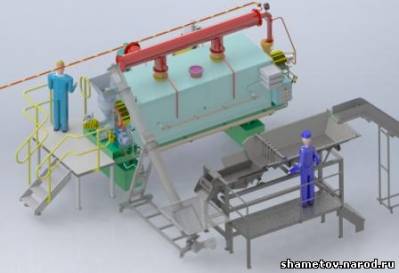

..Mini Installation activation MS20, indirect heating rotating furnace, steam heat, chemical processing of bulk materials.

1. Use for active coal of various grades of sorbents:

Wastes of wood, coal, peat, bone, bones, shells, nuts

-carbon residue of pyrolysis of tires;

-carbonaceous ore raw materials

-ore raw materials. For example, in the manufacture of clays, earths, various adsorbents used in fat and oil, sugar, alcohol, beer, etc. industry ...

2. regeneration, reactivation of sorbents and active (activated) coals.

3. drying, roasting, baking mineral raw materials. For example, to produce a variety of construction materials, or their enrichment.

4. drying, roasting, calcining industrial waste, obtaining different construction materials, sorbents.

Sincerely,

Marsel M. Sh.

Ltd. "Carbon"

Russia, Kazan.

+79872856084

http://www.shametov.narod.ru/

shametov@mail.ru,

shametovm@yahoo.com

shametov@yandex.ru

shametovm@gmail.com

|